|

摘要

本文介绍缺陷测深的方案和应用情况

主题词

测深研究采用渗透检测法来实现此目的

序言

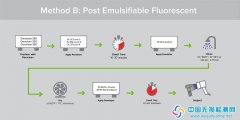

根据断裂力学极限寿命的分析,最危险是表面开口缺陷,即使微细的缺陷也最易于扩展延伸以致最终断裂。但是极限寿命中还存在着裂纹深度;这是最关键性的。在表面发现开口缺陷的大小来判断极限寿命是不完整的,因为深度因素有很大危害性,特别是内部向外延伸的缺陷。深度越深,危险性越大,因而在决定极限寿命时,必须采用简便的渗透检测技术来判断估计缺陷的深度,无损检测资源网从而分析缺陷的性质,达到更理想的效果。 技术指标-----最高测试范围:测深为:宽1μ以下,深1丝以下均可实施 采用吸附性能强的作用力来多次重复显示。即涂在检测表面渗透液即为收缩,并能将渗透到缺陷中的液体向外渗出,渗出越多,说明深度越深的特性。并可从宽度、深度缺陷的标尺中找出数据。即关键在于渗透剂具有特殊性能才可达到此项目的检测。

国内外均未有此类技术资料报导;如:断口形貌的观察;低周疲劳裂纹的形貌一般很难观察,但随着循环周次的增高,裂纹的扩展区也逐渐显明。主要是采用渗透液对断口留印,能清晰地看到当疲劳裂纹前缘扩展到一定程度时,其他薄弱环节的裂纹又以新的核心按弧形方式向前推进,随后连成一片,直至穿壁。这种现象起因于多重形核;首先扩展的裂纹受到了韧带的阻滞,使新的形核中心优先发展。而欧美等国家均采用酸洗留印,这是无法分辨疲劳区及韧带区的。

上述是经疲劳后泄漏的断口分析。

也可采用:

a、自然裂纹试块进行测试

b、通过重复多次显示能力得出缺陷深度

c、解剖分析

d、列出宽度、深度缺陷的标尺

通过二、三十多年来的实践,证实了此方法是行之有效的。得到专家的认定,并推广应用。 采用新型环保无污染渗透探伤剂(无需用显像液)更能方便快捷达到更安全可靠的检测结果。

Research and Application of Measurement of Defect Depth

Gui Jinhua, Chen Hongwei

Abstract:

In this paper, proposals and application of measurement of defect depth were introduced.

Key words:

The penetration detection method is adopted to realize the objective of depth measurement.

Introduction

According to analysis on limit life in fracture mechanics, the most dangerous defect is the surface opening defect. Even minor defects is very easy to expand and extend, causing final fracture. However, crack depth also exists in limit life, which is the most important. It is incomplete to determine the limit life through size of the opening defects found on surfaces because the factor of depth has very large hazards, especially defects extending from interior to exterior. The larger the depth is, the larger is the hazard. Therefore, the simple penetration detection technology should be used to judge and estimate depth of defects during determination of the limit life, so as to analyze properties of the defect and to reach more ideal effects.

Technical specifications ------maximum test range: for depth measurement: it can be implemented for width below 1μm and depth below 1decimillimetre.

1. The acting force with strong adsorption is used to repeated display. Namely, the penetrant coated on detection surfaces can shrink immediately and liquids penetrating into defects can seep outwardly. The more the liquids seeping, the deeper the depth is. Moreover, the data can be found from scales of the width and depth defects. The key is that detection of the item can be realized only if the penetrant has special properties.

2. No report on this type of technological information exists at home and in foreign countries, such as observations on appearance of fractures. It is generally difficult to observe appearance of low cycle fatigue cracks. However, the extension area of crack will become obvious gradually with increase of cycle times. http://www.jinshuyingduji.com In the method, penetrant is adopted to mark on the fracture, so that it can be clearly seen that cracks in other weak portions advance in new core at arc direction when the front edge of the fatigue crack extends to certain extent and then these cracks are connected together until the wall is penetrated. Such a phenomenon is originated from multiple nucleations. The cracks firstly extending are subject to blocking of ligaments so that the new nucleation centers develop preferentially. The acid washing marking technology is adopted in Europe and America, but the method is incapable of distinguishing the fatigue area from the ligament area.

The above is analysis on fracture leaking after fatigue.

The following methods can also be adopted:

a、Tests of pieces with natural cracks

b、Obtaining depth of defects through repeated display capability

c、Anatomy analysis

d、Listing scales of width and depth defects

2) The above said method can be used to detect material strength, limit life and properties of defects, so as to provide reliable foundations for implementation of failure analysis. The method can be used in such fields as national defense, traffic, equipment, power station, medical and health. At the same time, it provides valuable information in high speed, high pressure, high temperature and high-tech and top scientific fields.

Through more than thirty years of practices, it is proven that the method is feasible. It obtains acknowledgement of experts and is promoted.

Adoption of novel environmental protection pollution-free penetration detecting agent (no need of developing agent) can realize safer and more reliable detection results faster and more rapidly.

|

手机版

手机版